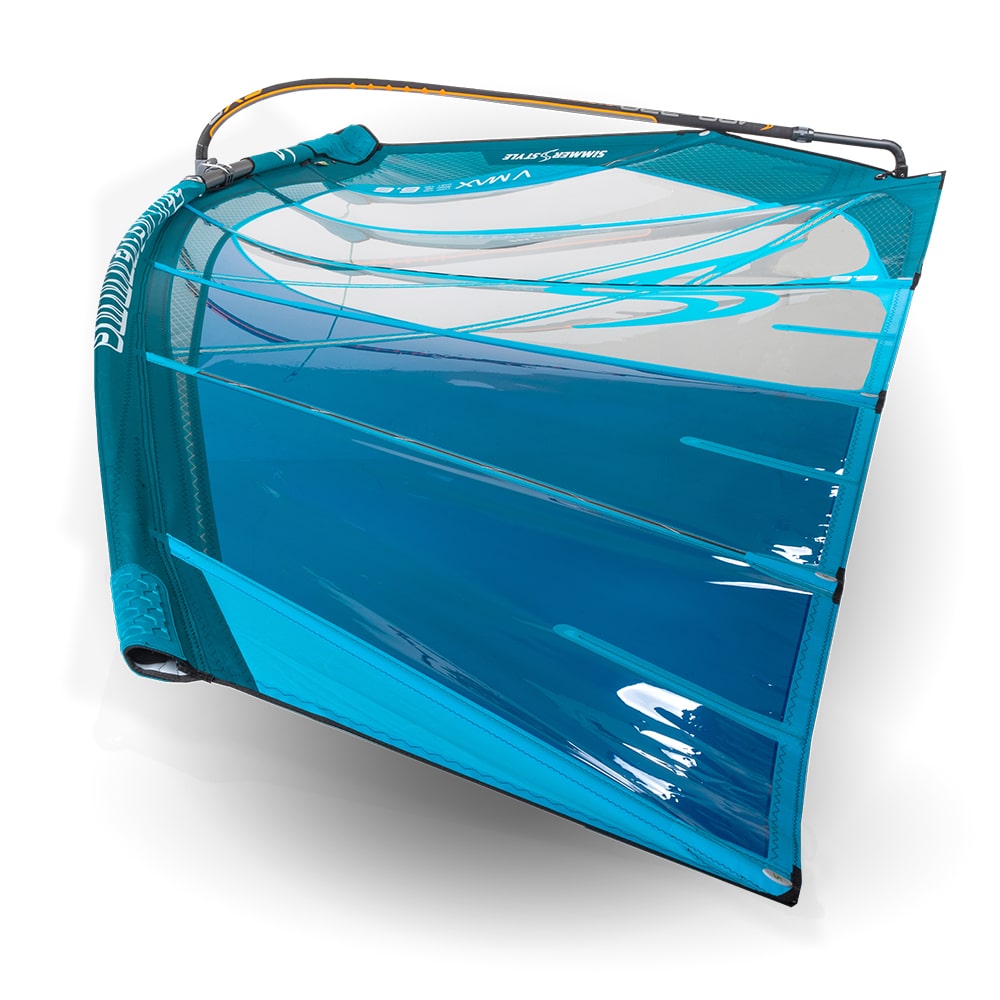

We build windsurfing equipment to last, subjecting them to brutal punishment, in the world’s toughest test labs - Hookipa, Jaws, Gnaraloo, Pozo, Punta Preta and Luderitz only to mention a few.

Before any Simmer Style product lands on the market, our team of world class athletes have tested and tortured countless prototypes and pre-production samples, in all conceivable conditions. From the world’s finest reef and point breaks to our local backyard beach breaks. From onshore blasting wind, to side offshore groomed perfection, and everything in between. Our resourceful team’s determination and energy, combined with our company’s experience from over four decades of developing top notch windsurfing sails. This is what makes the unique identity of what we produce, making every Simmer Style product stand alone. The performance and reliability of our sails, boards, and accessories are consistently pushing into new realms of capability.

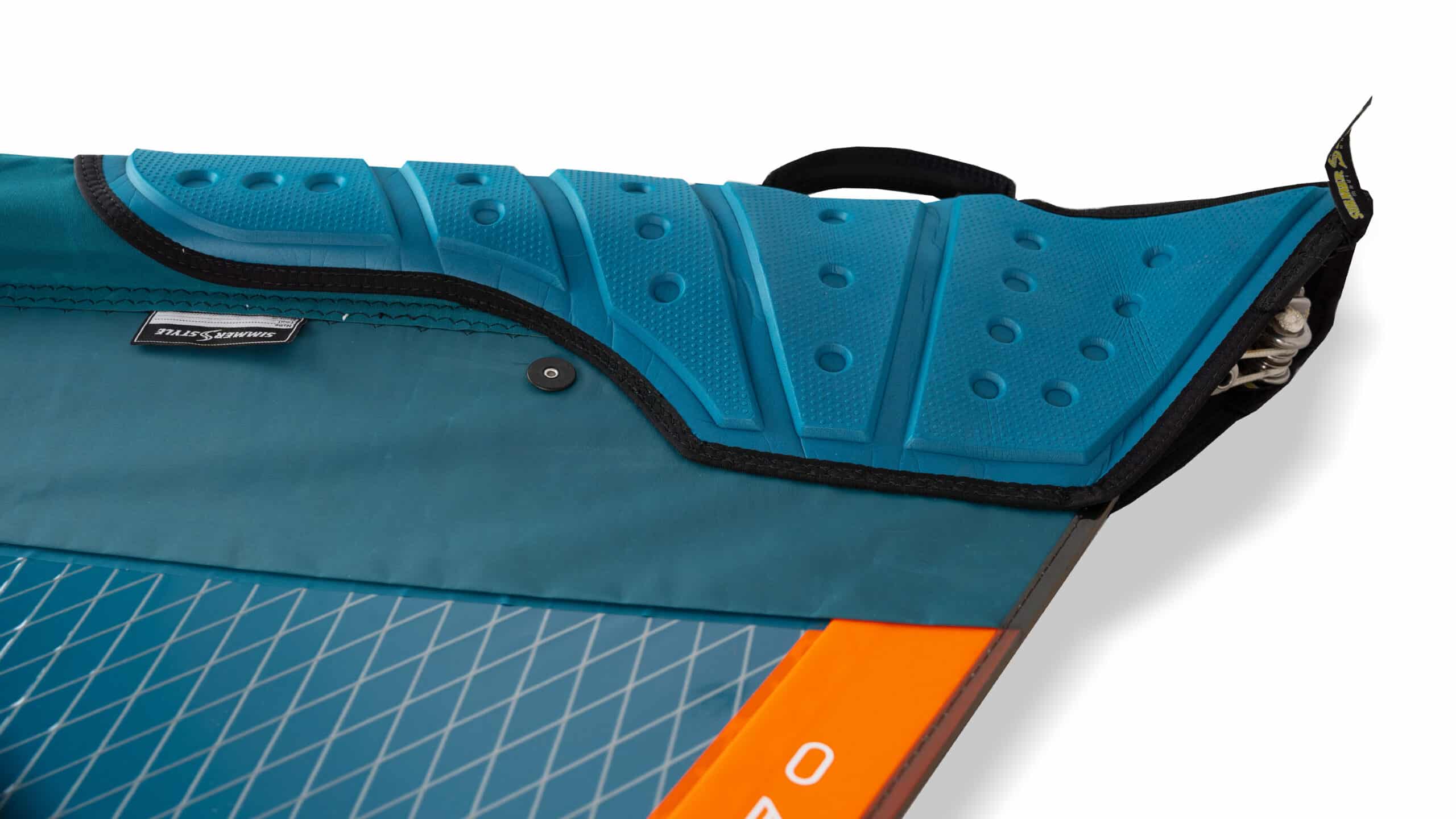

Quality, performance and innovation is not just a slogan.

It’s a fact.